Beck Manufacturing and Plant Capacity Read the “Beck Manufacturing , management homework help

Ace your studies with our custom writing services! We've got your back for top grades and timely submissions, so you can say goodbye to the stress. Trust us to get you there!

Order a Similar Paper Order a Different Paper

Beck Manufacturing and Plant Capacity

Read the “Beck Manufacturing” case study in Chapter 8 of your text. In a three- to four-page paper, address the following:

- Calculate the capacity of each machine center and the capacity of the system.

- Analyze where the focus of the company’s efforts should be if Beck wants to expand capacity. Determine how much extra capacity he can get without causing another operation to become the bottleneck.

- Suggest ways Beck can expand capacity without purchasing new equipment.

Your paper should be in paragraph form (avoid the use of bullet points) and supported with the concepts outlined in your text and additional scholarly sources.

Submit your three- to four-page paper (not including the title and reference pages). Your paper must be formatted according to APA style as outlined in and must cite at least three scholarly sources in addition to the textbook.

Beck Manufacturing

Al Beck, president of Beck manufacturing, wants to determine the capacity of his facility, which produces steering gears for auto manufacturers. He has asked you to sort through the data and determine the capacity of the system and how that capacity may be increased. The operation is a product layout that produces large numbers of nearly identical products. The process includes milling, grinding, boring, drilling, and assembling, in that order. Each finished product requires one operation on each type of machine. For example, each finished part is processed on one of the five milling machines, one of the seven grinding machines, etc.

The facility runs two 8-hour shifts per day, with a third shift for maintenance. The industrial engineering department has provided you with the following data on present operations. In addition, you have been told that assembly operations, while not unlimited, can be easily changed to meet the need.

| Operation | Number ofMachines | Run Time per Piece(min.) | % Reject Rate |

| Milling | 5 | 2 | 3 |

| Grinding | 7 | 3 | 5 |

| Boring | 3 | 1 | 2 |

| Drilling | 6 | 2.5 | 7 |

- Calculate the capacity of each machine center and the capacity of the system.

- If Beck wants to expand capacity, where should he focus the company’s efforts? How much extra capacity can he get without causing another operation to become the bottleneck?

- How may Mr. Beck expand capacity without purchasing new equipment? Be specific.

Discussion Questions

Click on each question to reveal the answer.

- What is capacity, and why is it important?

- Why is it difficult to estimate capacity? Is capacity a constant? Why or why not?

- Should an organization always attempt to match its capacity to its estimate of demand? Why or why not?

- Capacity decisions are strategically important. Agree or disagree with the statement, and support your position.

- What factors influence the capacity of an organization? List three factors, and explain how they influence capacity.

- Explain in detail the difference between departmental and system capacity.

- What are the principles for determining system capacity in the product layout?

- What are the principles for determining system capacity in the process layout?

- How does a change in the product mix effect system capacity?

- What are the important decisions for capacity planners?

- What are the key factors that determine when to add capacity?

- What are the key factors that determine how much capacity to add?

- Why would an organization want to reduce its capacity?

Problems

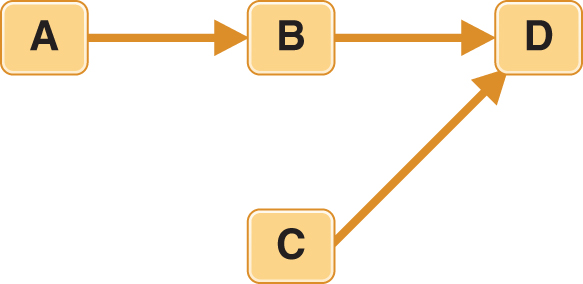

- Determine the system capacity and the bottleneck department in the following line flow process. The capacities in pieces per hour for departments A, B, and C are 5,250, 4,650, and 5,300, respectively.

- Determine the system capacity and the bottleneck department in the following line flow process. The capacities in tons per hour for departments A, B, C, and D are 2,200, 1,100, 1,600, and 2,500, respectively. For each ton of output from depart�ment B that is input to department D, two tons from department C must be added.

- Answer the following questions using the information in Problem 2:

- How much can the system capacity be increased by adding capacity to the bottleneck department?

- How much capacity must be added to the bottleneck department to achieve this increase in system capacity?

- Which department is the new bottleneck department?

- Examine the following line flow process:

- Determine the system capacity.

- Determine which department is the bottleneck.

- Determine how much capacity can be gained by adding capacity to the bottleneck.

- Explain your answers to a, b, and c.

- How would the analysis change if department A achieved an 85% yield? Recalculate a, b, and c.

Department Capacity (Parts/Hour) A 120 B 110 C 140 D 160 - Macro Galvanizing coats sheet steel for the appliance industry in its plant in Gary, Indiana. Macro has one production line that can coat steel up to 72 inches wide. The production line runs 80 hours per week. Regardless of width, the steel is processed at 200 feet per minute. Macro processes only the three widths of steel listed here:

Width (in.) Product Mix 36 0.30 50 0.25 60 0.45 - What is the capacity of Macro’s production line in square feet of steel coated per week?

- What is the capacity in square feet per week if the mix changes to 0.40, 0.40, and 0.20, respectively?

- What is the capacity in square feet per week if the mix does not change and Macro decides to use 10% overtime per week?

- What is the capacity in square feet per week if the mix does not change, there is no overtime, and Macro experiences 5% unplanned downtime?

- What is the capacity in square feet per week if the mix does not change, there is no overtime, and Macro’s engineers find a way to run the line at 220 feet per minute?

- Monique Food Processing Company produces light snacks that can be heated in a microwave. The following steps are included in the process:

Steps Description Capacity (Units/Hour) 1 Prepare food 200 2 Measure and place in plastic pouch 175 3 Prepare cardboard box 200 4 Insert pouch into box 300 5 Shrink-wrap box 200 - What is the system capacity, and which is the bottleneck department?

- How much slack (unused capacity) is available in other departments?

- How much system capacity can be gained by adding capacity to the bottleneck?

- Botkins Bicycle Shop manufactures 10-speed bikes. The assembly process requires the components listed below. Botkins can assemble approximately 350 bicycles per week without overtime. The labor contract allows Botkins’ management to add up to 10% overtime to assembly operations.

Component Quantity per FinishedBicycle Source Capacity(Units/Week) Wheels 2 Internal 750 Tires 2 External 900 Frame 1 Internal 400 Brakes 2 External 950 Handle bars 1 Internal 600 Pedal and drive sprocket subassembly 1 Internal 500 - What is the capacity of the facility without using overtime? Which is the bottleneck department(s)?

- What is the capacity of the facility with overtime? Which is the bottleneck department(s)?

- What increases in department capacity would be required to increase system capacity to 450 units per week?

- The Mills Brothers Cereal Company makes a wheat and raisin cereal on one of its production lines. One pound of raisins is required for four pounds of wheat flakes in order to make five pounds of cereal. The following steps are included in the process:

Step Description Capacity(Pounds/Hour) A Crush wheat 1,400 B Form flakes 1,200 C Toast flakes 1,600 D Coat raisins 250 E Mix cereal and raisins 1,200 F Put mixture in box 1,100 G Place boxes in shipping containers 1,400

- What is the system capacity, and which is the bottleneck department?

- How much slack (unused capacity) is available in other departments?

- How much system capacity can be gained by adding capacity to the bottleneck?

- White Chemical has a problem with its operations. Analyze the following flow process:

Department Capacity (Gallons/hour) A 100 B 60 C 50 D 120 E 100 F 40 G 140 The ratio for mixing the outputs from departments E and F is 2:1. This means that getting three gallons out of G requires mixing two gallons of E’s output and one gallon of F’s output. The ratio for departments B and C is 1:1.

- What is the system’s capacity?

- Which department(s) is the bottleneck?

- How much slack (unused capacity) is available in the other departments?

- How much system capacity can be gained by adding capacity to the bottleneck?

- Platinum Refining and Chemical Company is examining its pesticide plant. At this time, the company is unable to satisfy customer demand for a new insect spray. You have been asked to spend some time at the facility to determine how output can be increased. Analyze the following line flow process:

- What is the system capacity, and which is the bottleneck department?

- How much slack (unused capacity) is available in other departments?

- How much system capacity can be gained by adding capacity to the bottleneck?

- Bauer Electric makes integrated circuits for the computer industry. Currently, the process for making circuits yields 80% good parts. The facility has the capacity to produce 2,000,000 units per year, including both good and bad units. The variable cost is $2.00 per unit. The annual fixed cost is $10,000,000. The selling price is $12.00 per unit. Currently, the market demand exceeds the units available.

- If Bauer Electric works at capacity, what is the total amount of units produced in one year that meet specifications?

- If the yield can be increased from 80% to 90%, how much does the unit cost for a circuit change?

- If the yield can be increased from 80% to 90% and demand is unlimited, how much will profits increase?

- If the yield can be increased from 80% to 90% and demand is 1,600,000 units, what is the impact on profits?

- Why is there such a difference between the answers to c and d?

- McComas Educational Service provides training to pass the bar exam. The company offers a money back guarantee if a student does not pass on the first try. Currently, 60% pass the exam. The

| Department | Capacity (Gallons/Hour) |

| A | 300 |

| B | 250 |

| C | 200 |

| D | 250 |

| E | 600 |

| F | 550 |

| G | 600 |

| H | 1,100 |

| I | 300 |

| J | 1,200 |

The ratio for mixing the outputs from departments B, C, and D is 2:2:1, respectively. This means that making five gallons for department E requires mixing two gallons of B’s output, two gallons of C’s output, and one gallon of D’s output. The ratio for departments F and G is 1:1. The ratio for departments H and I is 4:1.

Looking for top-notch essay writing services? We've got you covered! Connect with our writing experts today. Placing your order is easy, taking less than 5 minutes. Click below to get started.

Order a Similar Paper Order a Different Paper